1200GS

Most Efficient, Reliable & Capable Blower

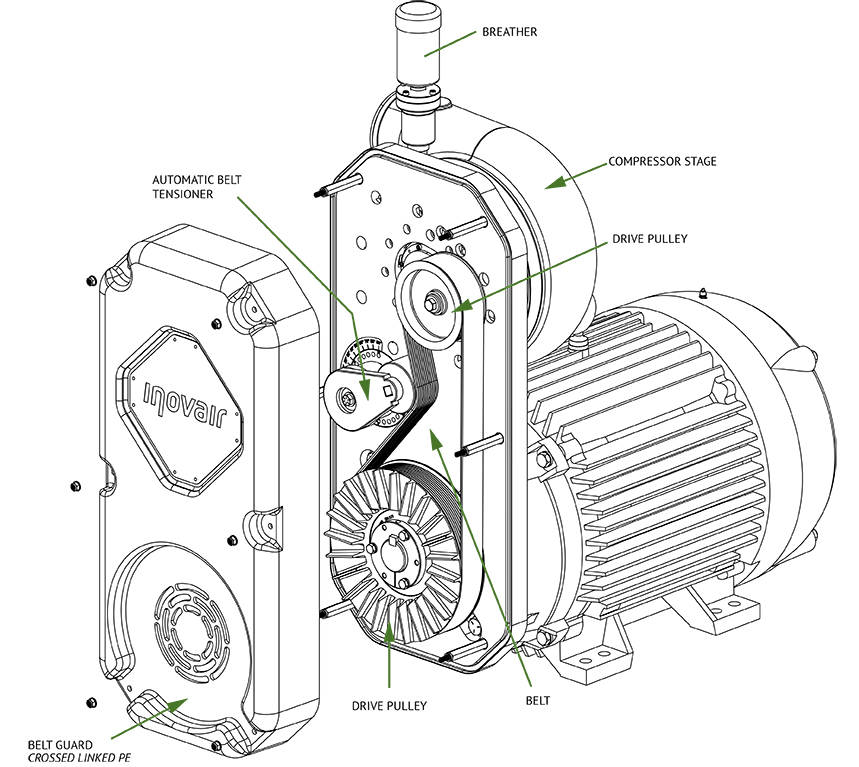

Get the ultimate in performance and durability with the Inovair 1200GS. Its advanced aerodynamics, with three models available and over a dozen aero-stages to choose from, offers the most optimal solution for your application. The unique drive system reduces belt wear and stress, and allows higher pressure and a broader operating range. Together, the efficiency and reliability lower your total cost of ownership.

Market-Leading Technology

Inovair’s compact centrifugal blowers lead the market. With performance, durability, and ease of use paramount in our design and development process, you will not find a better blower than Inovair’s. Optimized for flow and efficiency, the 1200GS delivers up to 1800 SCFM and up to 10 PSIG pressure, with peak isentropic efficiencies up to 81%. After nearly 30 years and over 35 patents developing and manufacturing centrifugal blowers, Inovair has proven durability on even the most challenging applications. Whatever your duty cycle requires, Inovair will deliver. Hands down, it will outperform the competition.

Inovair Advantages

| - Highest Reliability |

| - Class-Leading Efficiency |

| - Compact and Flexible Design |

| - Vertical and Horizontal Orientation |

| - Greatest Pressure Range |

| - Industry Leading Support |

| - Hassle-free Maintenance |

| - Designed and Made in the USA |

Technical Specifications

| Design Flow: Up to 1800 SCFM |

| Design Pressure: Up to 10 PSIG |

| Motor Power: Up to 60 HP |

| Drive: 50/60 Hz VFD |

| Inlet Temps: Up to 350 F |

| Operational Temps: -40°F to 160°F |

| Impeller: 5-axis machined 7075 T6 Aluminum |

| Lubrication: Centrifugally directed oil mist system |

| Seals: Aerospace-grade seals |

REPLACEMENTS FOR LEGACY BELT DRIVE UNITS

Looking to replace a legacy system? The Inovair 1200-Series are designed as drop-in replacements for legacy blowers utilized in HVAC carts for the GSE market, specifically the Vortron models J70, X70, and Z40E.

Highest Efficiency Aerodynamics

With decades of experience and proven capabilities, Inovair is able to deliver best-in-class efficiency and durability for your demanding applications. This high efficiency, thanks to state-of-the art compressor and gearbox designs, helps optimize both performance and energy consumption. From the impeller blade shapes and volute clearances to the materials and manufacturing processes employed, Inovair provides reliable performance matched perfectly and uniquely to each application.

More Robust Designs & Manufcturing

The 1200GS utilizes a rugged single-stage gearbox design with high precision helical gears and angular contact bearings, and a state-of-the-art aerospace carbon seal for oil-free air. Impellers are designed in-house and manufactured from 7075 T-6 aircraft aluminum on Inovair’s 5-axis CNC mills, which increases strength and avoids casting cracks or flaws. No competing product even remotely compares to the capabilities and durability of the 1200GS.

12 Options, Optimized Efficiency for Your Application

With three product models and more than twelve (12) different compressor options, each application is optimized for maximum efficiency. Compressor wheels are designed to have unique combinations of diameters (inducers and reducers), blade shapes, and number of blades. To control the air flow even more, compressor housings are engineered with different volute designs. Whatever your requirements, Inovair has the best blower solution that is optimized for any operating point of airflow. In high volume cases, custom aerodynamic designs have also been implemented.

Model Range

1200GS-3A

| DESIGN FLOW: Up to 1200 SCFM |

| DESIGN PRESSURE: 2-8 PSIG |

| MOTOR POWER: 10-60 HP |

1200GS-4A

| DESIGN FLOW: Up to 1500 SCFM |

| DESIGN PRESSURE: 2-8 PSIG |

| MOTOR POWER: 10-60 HP |

1200GS-5A

| DESIGN FLOW: Up to 1800 SCFM |

| DESIGN PRESSURE: 1.5-7.5 PSIG |

| MOTOR POWER: 10-60 HP |

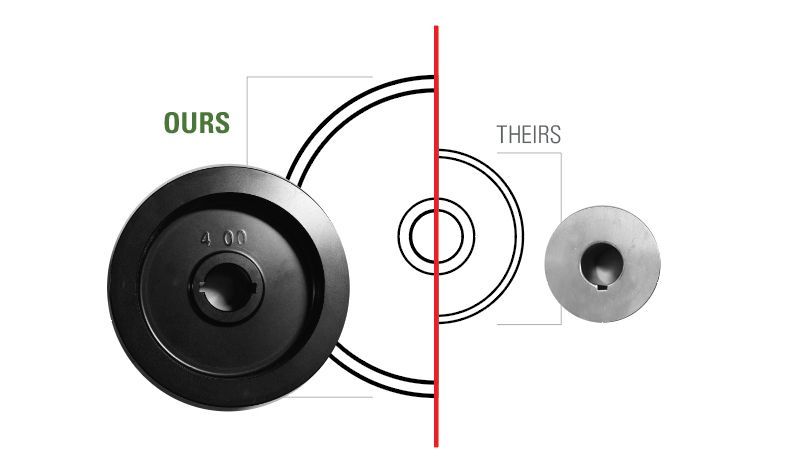

Most Durable Drive System

Our unique drive system is what makes the Inovair product so durable. No other product utilizes gearing like that on the Inovair 1200GS. Belts struggle with small diameter pulleys, as they cause more belt slippage and put a much high stress or load on the belt. The result is frequent belt changes and/or belt failure. By utilizing a gear step-up in the compressor head unit, the Inovair 1200GS has a significantly larger diameter blower pulley and, thus, a drastic improvement in belt life.

Designed, Manufactured & Serviced in the USA

When it comes to a supplier’s ability to deliver quality and availability, location matters. Inovair is not only headquartered in the heartland of America, but most operations, from engineering to manufacturing to service, are within the same facility. Our vertical integration means shorter leadtimes for parts and manufacturing. This creates a collaborative environment with lean design, manufacturing, and servicing practices. This product is also available for purchase direct from the Inovair factory.

Hassle-Free Maintenance

No more broken belts or frequent belt changes. Inovair products are designed to be maintained in the field by the equipment operator in just a few minutes. All our maintenance tasks have instructional videos on our website. Total cost of ownership includes the cost of servicing the unit for the useful life. Inovairs products are engineered to require the least effort and lowest cost to maintain.

Industry-Leading Support

Should an issue arise, Inovair technical and customer service, located at our headquarters in Kansas City, is ready to assist immediately. Our customers rave about the service Inovair provides before, during, and after the installation. Visit our website for testimonials on our superior service.

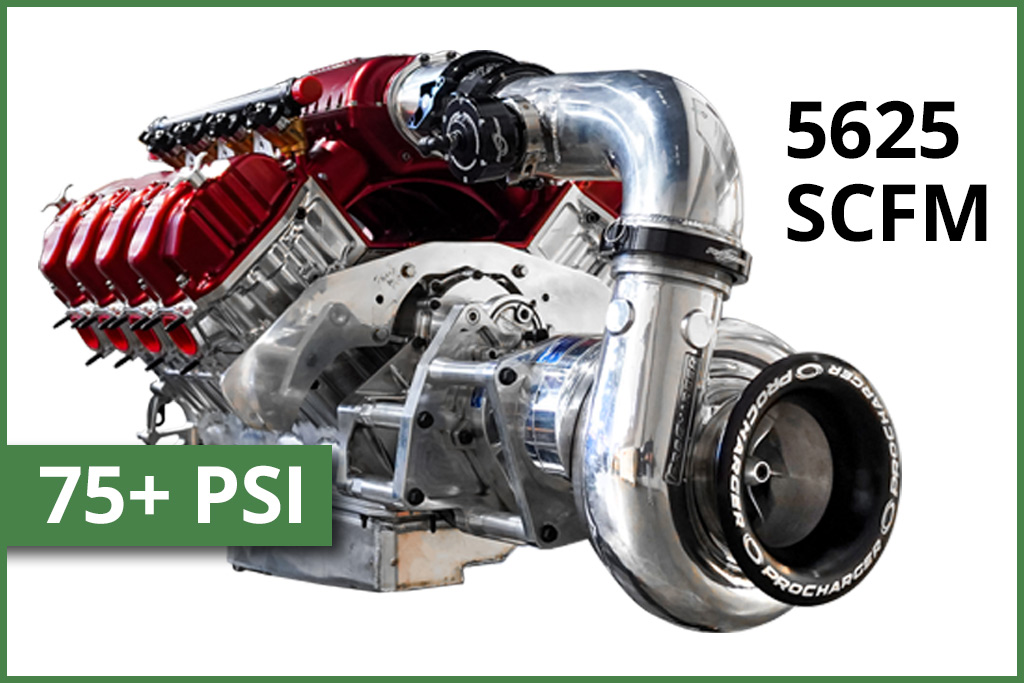

Top Manufacturer For Decades

Inovair has built a reputation over the past nearly 30 years for quality and excellence. As the #1 player in forced-air deicing, supplying exclusively to the US military and considered the “gold standard” for commercial airlines, Inovair is a trusted manufacturing partner. Our products are well known in the wastewater and general industrial industries for offering superior technologies and overall lowest cost of ownership. To complement our engineering efforts, we lean on our nearly 30 years of dominance as the leading automotive aftermarket supercharger supplier, where we serve applications up to 4000 hp in the most severe duty cycles imaginable.