Efficiency and Savings

Geared Centrifugal Blowers Are Substantially More Efficient

Efficiency translates directly into energy savings; the higher the efficiency of the blower, the larger amount of energy savings. According to a recent EPA report evaluating energy conservation measures, “Geared centrifugal blowers are a significant area of innovation in offering energy savings”1 Additionally, “single-stage centrifugal integrally geared blowers have the advantage of managing air flow and pressure independently,”1 allowing intelligent control and improved functionality, as well as energy savings.

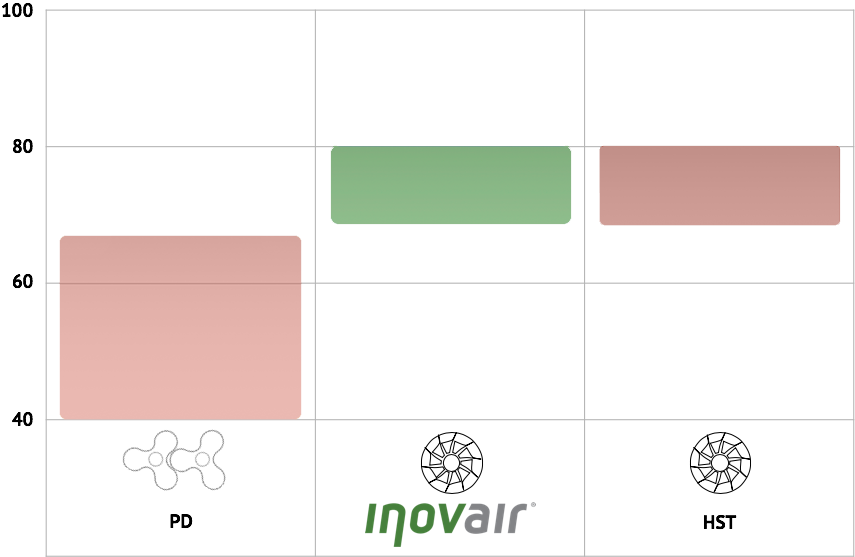

Typical Blower Efficiencies1

| BLOWER TYPE | NORMAL EFFICIENCY |

| Positive Displacement (variable speed) | 45-65% |

| Single-Stage Centrifugal, Integrally Geared (w/ inlet guide vanes, variable diffuser vanes) | 70-80% |

1EPA, Report 832-R-10-05, "Evaluation of Energy Conservation Measures" (September 2010)

Efficiency Advantage and Energy Savings

The energy demand for the water and wastewater industry is approximately 75 billion kilowatt hours per year, or about 3 percent of the electricity consumed in the US.1 Specifically, the aeration process at most wastewater treatment plants account for the largest amount of energy consumption and is as much as 40-60% of the plant’s total energy usage.

The energy demand for the water and wastewater industry is approximately 75 billion kilowatt hours per year, or about 3 percent of the electricity consumed in the US.1 Specifically, the aeration process at most wastewater treatment plants account for the largest amount of energy consumption and is as much as 40-60% of the plant’s total energy usage.Inovair offers high efficiency solutions for plants to significantly reduce energy usage, which typically results in tens of thousands of dollar savings in annual operating costs.

Inovair’s line of Geared Centrifugal Blowers offer 10-40% energy savings and a significant increase in efficiency over the traditionally used multi-stage blower or positive displacement blower equipment, Inovair’s integrated control systems also feature the ability to improve processes and process control for additional savings.

Relative to other modern single stage centrifugal/turbo technologies, Inovair geared centrifugal blowers offer comparable or better efficiency at a more economical price, and with greater reliability than air bearing turbos.

With the IM and IO Series of compact, high efficiency, integrally geared blowers, Inovair delivers an affordable solution which substantially reduces a wastewater plant’s total energy costs. The IO-Series offers the lowest cost per cfm, while the IM-Series offers an industry exclusive modular design and can also maintain operating levels of 75-85 dBA. Both models have a compact footprint and offer a wide range of airflow demands with a broad turn-down for various aeration requirements.

Geared Centrifugal Blowers are a significant area of innovation

According to a recent EPA publication2. Additionally, the EPA suggests "Equipment upgrades and operational modifications to reduce energy should not be one-time events, but should be incorporated into a comprehensive energy review and management strategy." Not surprisingly, high efficiency single stage centrifugal blowers have gained rapid acceptance in the wastewater industry in recent years, but air bearing turbos have not met expectations for reliability, and other turbo blower designs are not affordable for smaller plants.

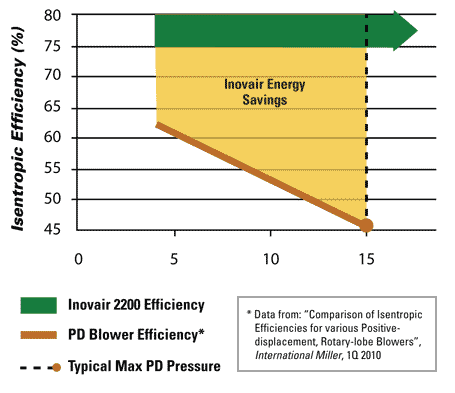

Isentropic Efficiency Comparison (%)

Efficiency = Energy Savings

Efficiency translates directly into energy savings; the higher the efficiency of the blower, the larger amount of energy savings. According to a recent EPA report evaluating energy conservation measures, beyond the efficiency advantage, "single-stage centrifugal integrally geared blowers have the advantage of managing air flow and pressure independently," 1 also allowing intelligent control and improved functionality.

Inovair is leading the way in technology with best-in-class efficiency at substantially lower costs relative to other centrifugal blower technologies.

• Inovair operates at a much higher efficiency (75-80%) than Positive Displacement blowers (PD blowers or roots blowers)

• Efficiency of PD blowers declines as pressure increases, enhancing the Inovair Advantage

• Choosing Inovair typically results in 10 to 35% energy savings over PD blowers (roots blowers)

Inovair is leading the way in technology with best-in-class efficiency at substantially lower costs relative to other centrifugal blower technologies.

• Inovair operates at a much higher efficiency (75-80%) than Positive Displacement blowers (PD blowers or roots blowers)

• Efficiency of PD blowers declines as pressure increases, enhancing the Inovair Advantage

• Choosing Inovair typically results in 10 to 35% energy savings over PD blowers (roots blowers)

Efficiency Advantage and Energy Savings Can Increase with Pressure