Wastewater Applications

Aeration

Aeration is an activated sludge process which has been around for over 100 years and is the most common process for waste water treatment. Two main processes are the aeration tank where oxygen is added to the wastewater and a settling tank where the sludge can settle. The oxygen is introduced into the liquor through diffusers.

Inovair has many installations in activated sludge plants throughout the United States. Inovair’s high efficiency and reliable design has allowed these facilities to run trouble free and realize significant energy savings over traditional blower technologies.

Inovair has many installations in activated sludge plants throughout the United States. Inovair’s high efficiency and reliable design has allowed these facilities to run trouble free and realize significant energy savings over traditional blower technologies.

Aerobic Digester

Aerobic Digester is a biological process that is used to reduce the volume of sludge with the introduction of oxygen. Bacteria in the activated sludge will consume organic matter in the presence of oxygen and convert it to carbon dioxide.

The varying water level of an aerobic digester has proven difficult for other technologies. Inovair’s advanced aero stages allow operation with water levels as low as 2' and as high as 30'. Additionally our integrally geared design with non-contact oil film bearings is ideal to use in any intermittent (start/stop) application.

The varying water level of an aerobic digester has proven difficult for other technologies. Inovair’s advanced aero stages allow operation with water levels as low as 2' and as high as 30'. Additionally our integrally geared design with non-contact oil film bearings is ideal to use in any intermittent (start/stop) application.

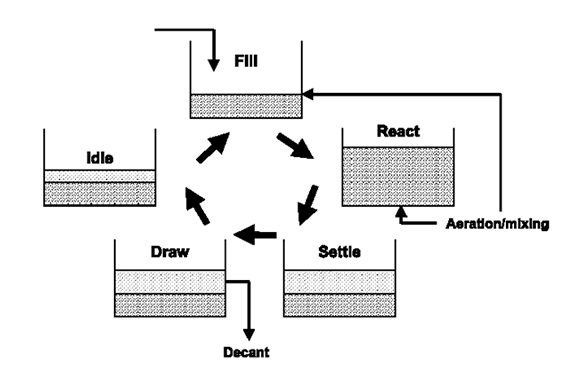

Sequential Batch Reactor (SBR)

SBR is a type of activated sludge process for the treatment of wastewater. The waste water is treated in batches and typically takes between 60-90 minutes. SBR’s can be used for wastewater treatment applications with low or intermittent flow conditions. The advantages of this system are reduced footprint, Equalization, primary clarification (in most cases), biological treatment, and secondary clarification can be achieved in a single reactor vessel, and operational and flexible control.

Inovair is uniquely designed to operate with the demands of the SBR process. Our integrally geared design with non-contact oil film bearings is ideal to use in any intermittent (start/stop) application. We have over 5 years proven service operating with SBR’s.

Inovair is uniquely designed to operate with the demands of the SBR process. Our integrally geared design with non-contact oil film bearings is ideal to use in any intermittent (start/stop) application. We have over 5 years proven service operating with SBR’s.

Membrane Reactor (MBR)

MBR is an activated sludge wastewater treatment system. An MBR combines membrane filtration (either micro filtration or ultra-filtration) and a biological waste treatment process. MBR’s are used for their ability to generate high quality effluent, small footprint, and is a very stable process.

Inovair’s integrally design is durable and reliable and is proven for any MBR. The high efficiency and lowest cost of ownership are a perfect match for your MBR.

Inovair’s integrally design is durable and reliable and is proven for any MBR. The high efficiency and lowest cost of ownership are a perfect match for your MBR.

Aerated Lagoon

Aerated Lagoon is a relatively simple wastewater treatment system consisting of a pond with artificial aeration to treat wastewater. Lagoons typically require large area and are shallower (typical depth 5'-15' than traditional aeration basins. Aerated lagoons require longer retention times.

Inovair’s lowest cost of ownership is ideal for any lagoon project. Inovair’s high efficiency, durability, and use of industry standard components allows aerated lagoon operators to cost effective and reliable operate their process. Inovair has over 5 years proven success operating in aerated lagoon applications.

Inovair’s lowest cost of ownership is ideal for any lagoon project. Inovair’s high efficiency, durability, and use of industry standard components allows aerated lagoon operators to cost effective and reliable operate their process. Inovair has over 5 years proven success operating in aerated lagoon applications.